A Template for an Undergraduate Elective Final Year Lift (Elevator) Engineering Course

Lutfi Al-Sharif

Professor, Mechatronics Engineering Department, The University of Jordan

Consultant, Peters Research Ltd.

Visiting Professor, The University of Northampton

This paper was presented at The 10th Symposium on Lift & Escalator Technology (CIBSE Lifts Group, The University of Northampton and LEIA) (2019). This web version © Peters Research Ltd 2019

Keywords: lift; lift traffic engineering; lift electrical engineering; lift mechanical engineering; guide rails; ropes; safety devices; safety gear; speed governor; electrical logic controller; electrical speed controller; traction motor; drive system; sensors and transducers.

Abstract. Lifts offer an ideal final year engineering capstone course, due to the multidisciplinary nature of its potential content. This paper sets out to develop a template for planning and delivering such a course at undergraduate engineering level based on experience gained at the School of Engineering at the University of Jordan.

There are basically four streams within this course: traffic analysis and design; space and layout planning; mechanical lift engineering and electrical lift engineering. Thus, it is ideal as a final year undergraduate elective course for mechanical, electrical and mechatronics engineering programmes.

The traffic engineering stream introduces the students to the basic concepts of the round-trip time, the interval, the handling capacity as well as basic introduction to the concept of group control and dispatching. The space and layout planning stream introduces the concepts of shaft dimensions, pit depth and headroom, as well as structural forces in the pit. The electrical stream introduces the student to the concept of a safety circuit and safety devices, DC and AC motors, drive systems as well as electronic logic controllers. The mechanical stream introduces the students to the main mechanical components such as gearboxes, ropes, safety gears, speed governors, sheaves, guide rails and buffers.

Providing such an introductory course in elevator engineering allows the students to reinforce concepts that they had studied earlier in non-applied basic courses and provides an opportunity to develop multi-disciplinary integrated design skills. The long-term aim of this project is to build an open access repertoire of study material, assessment tools and question banks as well as software that can be used to deliver and study the course.

1. Introduction

There is great emphasis in modern engineering education on project-based learning (PBL) and multidisciplinary engineering. It has been well recognised that lifts offer an ideal subject for the application of such projects, especially for electrical, mechanical and mechatronics engineering.

This paper is the result of experience by the author in delivering a final year elective course in the Department of Mechatronics Engineering at the School of Engineering, The University of Jordan. The course is entitled: “Selected Topics in Mechatronics Engineering” and can contain any content that is relevant to mechatronics engineering. The course has been delivered around the area of lift engineering around 6 times over the period between 2013 and 2018.

Based on the author’s personal experience, the feedback from the students regarding these courses has been very positive. Students enjoy this type of course because they feel it is linked to a real-life system and that it addresses real-life problems. In addition, the students are expected to work in a group on a project within the course, which allows them to reinforce some of the concepts by applying them in practice.

Similar work has been carried out on the Mechatronics System Design course for final year undergraduate students ([1], [2], [3]). Final year courses usually include a capstone course which aims to encourage the student to use all the concepts that they have learnt in a design project ([4], [5], [6], [7], [8], [9], [10], [11], [12]).

Section 2 outlines the contents of typical course. Section 3 lists and discusses typical topics that can be discussed in class to stimulate debate and discussion. Three typical course projects are discussed in Section 4. The three advantages of using lift engineering as the basis for this course are discussed in Section 5. Conclusions are drawn in Section 6.

2. Contents of a typical course

The course comprises four main streams: lift traffic engineering, lift space planning, lift electrical engineering and lift mechanical engineering.

The lift traffic engineering stream provides the students with a basic understanding of the methods of describing traffic in a building, the concept of the arrival rate (AR%) and the concept of handling capacity of the lift traffic system, the definition of the round trip time and how to find the suitable number of lifts to meet the required demand. A comprehensive set of resources that have been prepared especially for this course, entitled “Modern Elevator Traffic Engineering (METE) can be found in references ([13], [14], [15], [16]. [17], [18]. [19]), that have been adopted by others [20]. The students solve simple problems in finding the suitable number of lifts required for a certain building, establishing the interval as the index of the quality of service and the handling capacity as the index of the quantity of service. Student are also encouraged to use MATLAB to evaluate the Round-Trip Time using the Monte Carlo Simulation method [28]. A simple introduction to group control is given (an METE resource can be found in [21]), with some emphasis on sectoring as a tool for group control during incoming traffic. Graphical methods are also used to solve more advanced problems (the HARint Space [22]), in a way similar to the Root Locus Method developed by Evans used in control systems.

Under the lift space planning stream, the four critical dimensions of the lift shaft are explained: the shaft width, the shaft depth, the headroom and the pit depth. The use of the ISO 4190 standard is encouraged in order to find standard preferred sizes for car capacity, speed and shaft sizes. It is very appropriate at this stage to introduce the concept of preferred number and the concept of the Renard Series (R5, R10, R20 and R40) and the rationale for their use industry in general. An analysis of the forces that can occur on the pit floor are also discussed, based on the reaction force under the guide rails and the buffers.

In the lift electrical design stream, the general overview of the function of a logical controller is introduced. The concept of a safety device is discussed. The need to protect against one single failure taking place is presented practically by introducing possible failures in a control system and suggesting possible solutions to prevent them from causing a dangerous situation. An excellent resource for the concepts of safety in control systems can be found in [23] written by the Heath & Safety Executive (HSE). The whole system of a speed controller is also introduced with emphasis on the speed feedback device and associated concepts of stability and disturbance rejection. A good set of resources on drive systems and electrical machines can be found in ([24], [25], [26], [27]). The concept of cascade control is presented in the context of a closed loop feedback control of a dc motor drive lift. A detailed exercise on sizing an induction motor based on torque requirements and power requirements is carried out, based on achieving the required starting acceleration.

In the lift mechanical engineering stream, the students are introduced to the general mechanical arrangement of the traction lift, including the ropes, the sheave, the overspeed governor, the safety gear, the buffer system, the gearbox and the mechanical braking system. The main resource used for lift mechanical design was the textbook by Janovsky [29]. It is very useful at this point to get the students to gain a general appreciation of the integrated safety system that is made up of the mechanical brakes, the overspeed governor, the safety gear and the buffers and where each component’s contribution is required. This allows the student to understand that engineering designs need to be safe as well as functional; that the engineering designer needs to consider faulty conditions in addition to normal functional conditions. Sizing the ropes would be a useful exercise in order to understand the concept of the safety factor (16 for one single rope; 12 for two or more ropes). This introduces the student to the concept of a safety margin in design, which is a central concept in engineering design in all engineering disciplines.

3. Interesting examples of links to engineering topics

There are specific featured topics that attract a lot of interest and excitement from students and enrich the lecture environment by stimulating discussion. The following list includes some of these concepts that can be introduced or reinforced during the course:

Probability Calculations for the Traffic

Many of the important concepts of probability theory are encountered when deriving the basic equations for the round-trip time, such as the concept of the mean value of a random variable, independent events and conditional probability. These are needed when driving the expected number of stops (S) in a round trip and the expected value of the highest reversal floor (H). The use of Venn diagrams is a great tool for clarifying some of these concepts.

Using Queueing Theory to Calculate Waiting Time and Queue Lengths

The number of passengers waiting for a lift, the formation of queues and the operation of the lifts as servers are concepts ideally dealt with using queuing theory. A resource that explains the application of queueing theory to lift traffic systems can be found in [30]. Queuing theory has been used to find the value of the average waiting time and the average queue length under steady state conditions (i.e., when the lift system is subjected to a constant passenger arrival rate for a long period of time such that the system arrives at a steady state condition).

Kinematic Analysis Modelling

The development of the speed-time curve for a lift and the inclusion of the values of the rated jerk and rated acceleration can be introduced in a very interesting way when looking at the movement of the lift car. The students are encouraged to use MATLAB/Simulink to generate the curves and extract data from them. As will be seen later in the projects section, they can also use an accelerometer to measure acceleration from a real lift and extract the speed-against-time profile and the displacement-against-time profile.

Energy and Power Modelling of a Lift System

Energy modelling and simulation is also an interesting area that students can explore and research in more detail. For example, they calculate the amount of potential energy stored in the mechanical components such as the car and the counterweight, the translational and rotational kinetic energy stored in the masses and the inertias, respectively ([31], [32]). They can also calculate the frictional losses incurred in the shaft. They may also measure the actual power consumed and regenerated by the lift systems as it is moving upwards and downwards (and is the lift system is accelerating and decelerating).

The Space Lift and Rope Sizing for Lifts

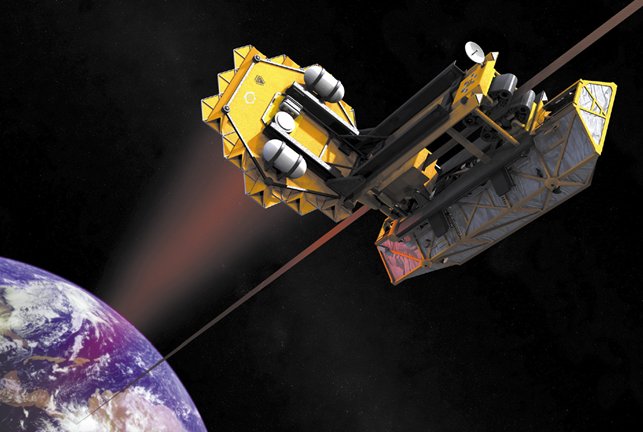

One of the main components that needs to be sized in lift systems is the diameter and number of ropes that must be used. This takes into consideration yield stress of steel ropes, the masses of the counterweight and the lift car, the masses of passengers, as well as the required safety factors to account for dynamic forces. Once students have carried out the sizing of ropes for a lift, it is interesting to ask them to find the limitation of steel ropes (e.g., current limit is around 600m assuming the safety factors are adhered to). This often leads to the discussion of using carbon nanotubes in the proposed space lift (Figure 1) that have a higher yield strength and lower density compared to steel ropes. Students find this topic thought provoking and fascinating. The students start to have an appreciation for the limitation placed on conventional materials and how they can be overcome with modern materials.

Figure 1: The Space Lift (and the use of carbon nanotubes to connect it to earth). Accessed on: 29th June 2019: https://spectrum.ieee.org/aerospace/space-flight/a-hoist-to-the-heavens

Buckling in Guide Rails

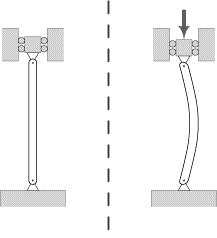

When considering the distance between the fixing for guide rails, one of the items that must be considered is the risk of buckling. Buckling is a topic that is often included in Strength of Materials courses (Figure 2). Euler’s formula is used to decide if buckling will take place, and if so, the critical distance between fixing points that will prevent buckling.

Figure 2: The concept of buckling in slender element subjected to compression.

4. Possible course projects

As this course is usually run for final year students, it is ideally placed to include a project within it. Students are asked to work in groups of 2 or 3. A number of suggested projects are offered to students to work on. They are usually given a period of 4 to 6 weeks. More details about the application of project-based learning (PBL) in undergraduate engineering education can be found in [33]. Some of the more interesting projects are discussed in this section.

Lift Kinematics Measurement and Filtering

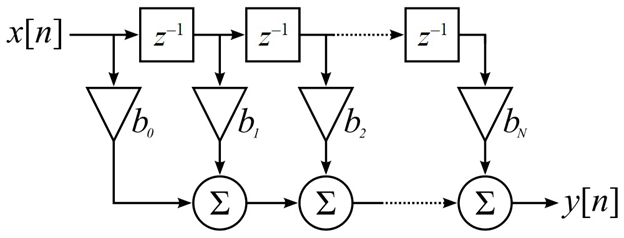

One of the most popular projects that the students enjoyed was measuring the lift kinematics from a real lift and processing the results. The students borrowed a dedicated accelerometer, or they install an application on their tablet or smart phone. This is then used inside a lift to measure the raw acceleration. The students then are taught how to design a suitable second order digital filter. The block diagram of a digital filter is shown in Figure 3.

Figure 3: A block diagram of a digital filter.

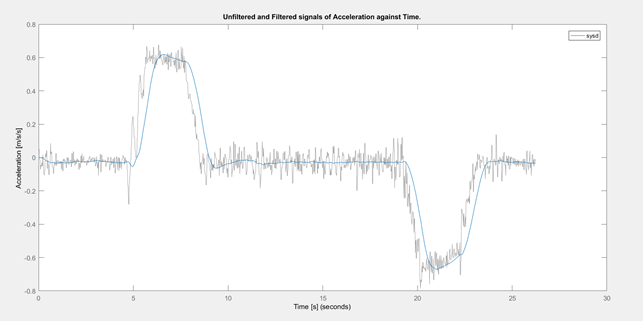

Once the students have designed a suitable digital filter in MATLAB, they import the raw captured acceleration data. This is then passed through the second order digital filter for filtering the acceleration signal. One of the results obtained is shown in Figure 4. The figure shows the raw acceleration data before filtering the filtered acceleration signal. It can be clearly seen how the filter has removed the high frequency noisy signal and kept the low frequency acceleration signal.

Figure 4: A digital filter used to filter the acceleration data captured from a lift.

Traction Motor Sizing and Selection

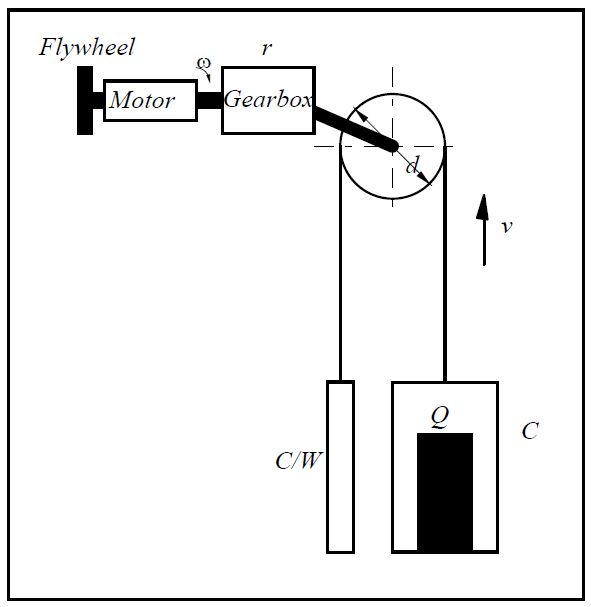

Another one of the popular projects is the sizing and selection of the traction motor for the lift. A set of equations are developed that include the masses and the inertias in the lift components, the speed reduction ratio of the gearbox, the diameter of the traction sheave and the details of the traction ropes [34]. These equations are then used in order to calculate the required torque from the motor that would achieve the required value of the starting acceleration. An overview of the motor, gearbox, sheave, traction ropes, car and counterweight is shown in Figure 5.

Figure 5: Sizing and selecting a suitable induction motor for the lift.

Passenger survey in a building

The group of students would arrange to visit a building and carry out a passenger survey. They work in a group and synchronise their watches. They have a special form prepared in which they enter the arrival time of each passenger. They also collect data about the number of occupants on every floor, and they carry out an accelerometer measurement in order to obtain the rated speed, rated acceleration and rated jerk of the lift as well as the floor to floor distance. Using all of the data obtained, they assess the passenger arrival rate (AR%) and then they reverse design the lift traffic system in the building.

5. Advantages of these types of courses

There are three main advantages of using a lift engineering course to deliver certain concepts in engineering.

- Students are always pointing out that they will be more engaged in their studies if they understood the real-life applications of the topics. Most of the topics and problems presented in this course represent real-life applications and problems. Thus, they are more appealing to students as they can better understand the need for analysing these applications and solving the associated problems.

- The nature of lift engineering is ideal for project-based learning. Thus, students can be given a project that is very practical in nature. They can work on it in teams, solve problems, and learn by doing things.

- Lift systems by their very nature are multidisciplinary. The students can thus deal with problems that straddle multiple disciplines, such as mechanical engineering, electrical engineering, control engineering, programming and operational research. This is much more representative of real-life problems and better prepares the students for the marketplace.

6. Conclusions

It is well established that courses that address real-life multi-functional systems are ideal and examples include but are not limited to: automotive systems, manufacturing systems, aircraft systems and robotic systems. These represent ideal capstone projects for students, due to their practical nature and the multiplicity of disciplines that they comprise.

This paper has outlined a template for using lift engineering as the basis for such a final year course as part of an undergraduate engineering degree (in mechanical engineering, electrical engineering or mechatronics engineering). Four distinct streams have been identified and detailed: lift traffic engineering, space layout and planning, lift electrical engineering (include logic control, safety devices and speed control) and lift mechanical engineering.

The paper has also highlighted specific topics and links that present excellent opportunities to present and/or reinforce many concepts that the students traditionally study in dedicated courses (such as strength of materials, mechanics, electrical machines). These topics always attract a lot of interest from students and stimulate interesting and thought-provoking debates in class. Examples include: rope sizing and the space lift; and buckling in guide rails.

Project-based learning (PBL) presents an excellent tool to encourage student to learn the topics by working practically on them and gathering real-life information. Three examples were given: measuring the acceleration of a lift and filtering the data using a second order digital filter, sizing and selecting the traction motor for a geared lift and carrying out a traffic survey in a building and reverse designing the traffic system.

It has been explained that there are three reasons why this approach is successful in encouraging students to better learn the engineering concepts: the fact that students understand why they are studying a topic because they can see its real-life applications, lift engineering is ideal for project based learning (as there are many lift systems that are everywhere and accessible) and the multidisciplinary nature of the lift engineering system that is ideal for preparing the students for real-life engineering.

The long-term aim of this work is to develop an open online repertoire of resources for delivering this course at any school of engineering around the world.

REFERENCES

- Al-Sharif, L. Twenty engineering principles for undergraduate mechatronics engineering students. 7th International Symposium on Mechatronics and its Applications, Sharjah, UAE, 2010.

- Al-Sharif L, Saleem A and Tutunji T A. Mechatronic system design: The ideal capstone course? 7th International Symposium on Mechatronics and its Applications, Sharjah, UAE, 2010.

- Al-Sharif L, Tutunji T A, Ragab D and Kayfi R. Using Elevator system modelling and simulation for integrated learning in mechatronics engineering. 15th International Workshop on Research and Education in Mechatronics (REM), 2014; pp 1-8.

- de Silva C W. Mechatronics: An integrated approach. CRC Press, 2005.

- Jarrah M A. Teaching Mechatronics Design Course for Engineers. IEEE Workshop on Advanced Robotics and Its Social Impacts, 2005.

- Tutunji T, Saleem A and Abd Rabbo S. An Undergraduate Mechatronics Project Class at Philadelphia University, Jordan: Methodology and Experience. IEEE Transactions on Education, Vol. 52, No. 3 August 2009.

- Goldberg J R. Helping students recognize the value of capstone design courses. IEEE Engineering in Biology and Medicine Magazine, May/June 2009.

- Goldberg J R. Preparing students for capstone design. IEEE Engineering in Biology and Medicine Magazine, Nov/Dec 2009.

- Gruenther K, Bailey R, Wilson J, Plucker C and Hashmi H. The influence of prior industry experience and multidisciplinary teamwork on student design learning in a capstone design course. Design Studies 30, 721-736, 2009.

- Isomottonen V and Karkkainen T. The value of a real customer in a capstone project. 21st Conference on Software Engineering Education and Training, Proceedings, Engineering Education and Training pages 85-92, 2008.

- Pieper J. Work in progress: A capstone course in practical control systems through mechatronics. 36th Annual Frontiers in Education, Conference Program, Vols 1-4 – Borders: International, Social and Cultural, pages 18-19, 2006.

- Benaroya H. Lunar base design: A paradigm for the capstone design course. Aerospace and Electronic Systems Magazine, IEEE, Volume 21, Issue 7, pages 33-36, July 2006.

- Al-Sharif L. Introduction and Assessing Demand in Elevator Traffic Systems (METE I). Lift Report 2014; 40(4): 16-24. July/August 2014.

- Al-Sharif L. Calculating the Elevator Round Trip Time for the Most Basic of Cases (METE II). Lift Report 2014; 40(5): 18-30. Sep/Oct 2014.

- Al-Sharif L. Intermediate Elevator Kinematics and Preferred Numbers (METE III). Lift Report 2014; 40(6): 20-31. Nov/Dec 2014.

- Al-Sharif L. Four Special Cases in the Calculation of the Elevator Round Trip Time (METE IV). Lift Report 2015; 41(1): 22-36. Jan/Feb 2015.

- Al-Sharif L. Calculating the Elevator Round Trip Time for the General Case under Incoming Traffic Conditions (METE V). Lift Report 2015; 41(2): 24-37. Mar/Apr 2015.

- Al-Sharif L. Introductory Elevator Traffic System Design (METE VI). Lift Report 2015; 41(3): 32-44. May/Jun 2015.

- Al-Sharif L. The Average Waiting Time and the Average Travelling Time (METE VII). Lift Report 2015; 41(4): 34-45. July/August 2015.

- Drewer S. Development of tools for planning and comparison of elevators, Ph.D. Thesis. Karlsruhe Institute of Technology, November 2015.

- Al-Sharif L. Introduction to Elevator Group Control (METE XI). Lift Report 2016; 42(2):59-68.

- Al-Sharif L, Abdel Aal O F, Abu Alqumsan A M and Abuzayyad M A. The HARint Space: A Methodology for Compliant Elevator Traffic Designs. Building Services Engineering Research & Technology, 2015; 36(1): 34–50.

- HSE Books. Out of Control: Why control systems go wrong and how to prevent failure. Health and Safety Executive, United Kingdom, 2nd Edition, 2003, HSE Books.

- Wildi T. Electrical Machines Drives and Power Systems. 6th Edition, Pearson Prentice Hall.

- Crowder R. Electric Drives and Electromechanical Systems. Newnes, 2006.

- Shepherd D, Hully L N and Liang DTW. Power Electronics and Motor Control. Cambridge University Press, 2nd Edition, 1995.

- Chapman S J. Electric Machinery Fundamentals. McGraw Hill International Edition, 1991.

- Al-Sharif L. MATLAB CODE TO EVALUATE THE ELEVATOR ROUND TRIP TIME USING MCS The Use of In-Class Problem Based Learning for Final Year Engineering Students. Lift Report 2018; 44(1): 14-20.

- Janovsky L. Elevator Mechanical Design. 3rd edition

- Al-Sharif L, Abu Alqumsan A M, Ghanem W, Tayeh I and Jarrar A. Modelling of Elevator Traffic Systems Using Queuing Theory. 4th Symposium on Lift and Escalator Technologies 2014. Vol 4, pp 9-18. University of Northampton, September 2014. doi: 10.13140/RG.2.1.1392.0165.

- Al-Sharif L. Lift and Escalator energy consumption. Proceedings of the CIBSE/ASHRAE Joint National Conference, Harrogate 1996; 1: 231-239.

- Smith R S, Peters R D and Al-Sharif L R. Elevator system to minimize entrapment of passengers during a power failure. US Patent Number US7967113. Publication date: 28th June 2011.

- Al-Sharif L. Project Based Learning in Undergraduate Engineering Education. Professional Accreditation Conference for Engineering (PACE), Jordan Engineers’ Association, 25th March 2015, Amman, Jordan.

- Al-Sharif L. Lift and Escalator Motor Sizing with Calculations & Examples. Lift Report 1999; 52(1).

BIOGRAPHICAL DETAILS

Lutfi Al-Sharif is currently Professor of Building Transportation Systems at of the Department of Mechatronics Engineering, The University of Jordan. He received his Ph.D. in lift traffic analysis in 1992 from UMIST (Manchester, U.K.). He worked for 10 years for London Underground, London, United Kingdom in the area of lifts and escalators. He has around 30 papers published in peer reviewed journals the area of vertical transportation systems and is co-inventor of four patents and co-author of the 2nd edition of the Elevator Traffic Handbook. He is also a visiting professor at the University of Northampton (UK), member of the management committee of the annual Symposium on Lift & Escalator Technologies and a member of the editorial board of the journal Transportation Systems in Buildings.