Departure Delays in Lift Systems

Stefan Gerstenmeyer1,2, Richard Peters2,3, Rory Smith2,4

1thyssenkrupp Elevator Innovation GmbH

2The University of Northampton, UK

3Peters-Research Ltd.

4thyssenkrupp Elevator North America

Keywords: lift, elevator, multi car, departure delay, quality of service, transit time, waiting time, walking time, up-peak, door dwell, start delay

Abstract. There is a range of lift systems with more than one car or cabin per shaft. Double deck lifts have a car with two attached cabins, serving adjacent floors at the same time. Other systems enable two independent cars to share the same shaft. The next generation ropeless lifts will allow many cars to share the same shafts.

In these systems, the interaction between the cars and cabins affect the quality of service for passengers. Departure delays occur when passenger loading and unloading times or the sequence of stops required to serve passengers is not the same. The consequence is that cars and cabins delay each other’s departure. Departure delays can also occur in lift systems with a single car and cabin per shaft, for example, when destination calls are registered at a significant walking distance from the lift lobby.

To include departure delay in an assessment of quality of service, definitions of passenger and cabin departure delays, and a method to measure these delays are required. This paper describes the different types of departure delays and their causes. This provides metrics which can be applied in lift planning and dispatcher design.

1 Introduction

1.1 General

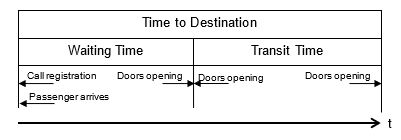

A passenger’s journey consists of two different phases (see Figure 1), waiting for the lift at the arrival floor, known as waiting time (WT), and the travelling time inside the cabin, known as transit time (TT). The sum of WT and TT is called time to destination (TTD) [1].

A lift stands with its doors open at a landing to allow passenger transfer. After the transfer of passengers has finished, the door closing and departure of the cabin may be delayed by the control system.

Why these departure delays occur and how they can be measured is defined and explained in this paper.

Figure 1 Passenger’s time to destination – phases of a journey

1.2 Extended door dwell time

Most modern lift controllers have intelligent door dwell time algorithms. The presence of passengers is detected by the photoelectric door protection devices. If the door beams are interrupted, the control system assumes that passenger transfer is occurring and the doors remain open.

Extended door dwell time is the time after the passenger detection beams of the doors are cleared before the lift door starts closing. Door dwell time before or during passenger transfer is not part of the extended door dwell time.

The extended door dwell time is a delay experienced by passengers inside the cabin. This includes passengers who have just entered the cabin and passengers who are already inside the cabin having an intermediate stop. During the extended door dwell time, nothing happens for the passengers. It can be observed that regular lift users often press the door close button in the cabin rather than waiting for the doors to start closing for themselves after the extended door dwell time. Extended door dwell time is experienced as departure delay.

1.3 Multi car lift systems

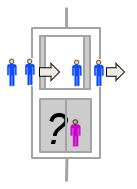

In multi car lift systems (MCLS), multiple lift cars or cabins share the same shaft, guide rails and shaft doors [2]. Systems with more than two independent lift cars are currently in development [3]. Existing double deck lift systems have two mechanically coupled lift cabins. Departure delays in multi cabin systems occur when the loading/unloading times of the cabins are different, the number of stops is not equal, or one cabin blocks the way of another [4]. An example is illustrated in Figure 2. In a MCLS cars may delay departure to avoid collision [5, 6]. The dispatcher may consider departure delays. They should be minimised, although in special instances a departure delay is the only option [7].

Figure 2 Double deck lift with a blind stop for a passenger in the lower cabin

1.4 Conventional systems

1.4.1 Up-peak

Departure delays are sometimes initiated by the dispatcher. In up-peak traffic conditions, it can be beneficial to delay a car’s departure from the lobby to wait for additional arriving passengers so that the cabin is filled to a higher capacity factor [8, 9]. It is recommended that passengers should not be held at the lobby for more that 10 to 15 s [9].

1.4.2 Walking times

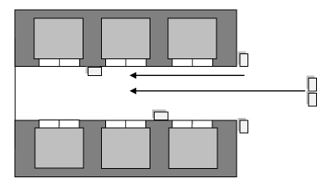

Delays may occur if passengers need to walk to an allocated and arriving lift car. In destination control systems, the walking time from a call input station to the allocated cabin (see Figure 3) is part of the waiting time of a passenger if the cabin has not yet arrived. As the walking time is part of the waiting time it can be considered as occupied waiting time which is less painful [4]. However, a passenger walking from a call input station to a cabin that is already standing with open doors at the arrival floor, delays the departure of the lift and any passengers who are already inside the cabin.

Door dwell time in conventional systems may need to be lengthened due to the arrangement of the lifts. In buildings built before lifts were automatic, it was common to place six or even eight lifts in a row. When these lifts were modernized, the dwell time needed to be long enough to permit passengers to walk from one end of the lobby to the other. Lift shafts may be arranged in line or opposite each other. Lift group layouts and lift lobby sizes affect the walking time. Long walking distances will delay the closure of cabin doors and will cause departure delays of cabins [1]. Also crowded lobbies can affect passenger transfer and cause delays.

Figure 3 Floor plan with walking distance from call input stations to the lifts

1.5 Stops without passenger transfer

1.5.1 False stop

A false stop is a stop where the doors open and close without any passenger transfer (see Figure 10). A false stop occurs if a waiting passenger walks away before the lift arrives [4]. The door dwell time during a false stop is a departure delay for passengers already inside the cabin. False stops can occur in multi car lift systems if an empty cabin is shunted (moved out of the way) with a car call to allow another cabin to reach its destination. No passenger is affected, so there is no contribution to departure delay.

1.5.2 Blind stop

A blind stop is a stop of a cabin with no door operation (see Figure 15). In general, blind stops should occur only without passengers inside the cabin [7]. Passengers who are inside the cabin are confused by blind stop situations.

In a conventional system, a blind stop occurs if a lift does not have an allocated call and the cabin is parked at a floor. Passengers are not affected by this kind of blind stop. In double deck lift systems, blind stops can occur if only one of the two cabins have passengers transferring. In multi car lift systems with independent cabins in the same shafts, blind stops with passengers inside the cabin should be rare.

1.6 Quality of service

Departure delays are confusing for lift passengers [4] and reduce the quality of service. A blind stop or any other departure delay should be explained to the passengers because unexplained waits seem longer than explained waits [10]. The use of a display in double deck cabins that states “serving other deck” when a blind stop occurs is recommended [11]. For all types of departure delays, information about a departure delay can reduce passenger’s anxiety about their service. However, even explained departure delays can be annoying for passengers if they are too long, as waiting needs to be appropriate [12].

There is a difference in the departure delay experienced by passengers if doors are opened or closed. A departure delay with the doors closed is known as a blind departure delay.

2 Samples/Records of Departure Delays

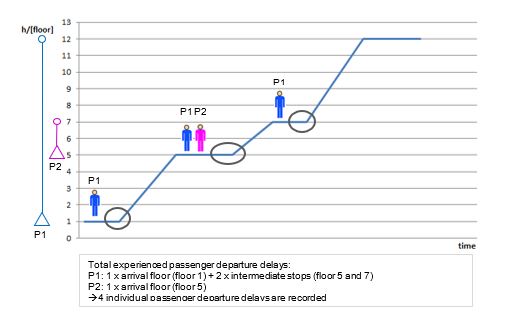

During a journey, passengers experience different stop times including departure delays. The first stop time is the arrival of the cabin at the passenger’s floor before it starts moving. Additional stop times during transit occur at the intermediate stops. The stop at the destination floor of the passenger is not a part of the passenger’s transit time. This is illustrated at Figure 4. In this example there are 4 passenger departure delays (PDD) that are experienced by two passengers (P1 and P2). Passenger 1 (P1) experiences 3 departures delays. Passenger 2 (P2) has only one departure delay. The cabin has 3 cabin departure delays (CDD) that are experienced at least by one passenger each.

Figure 4 Experienced departure delays

3 Passenger Departure Delay (Open Doors)

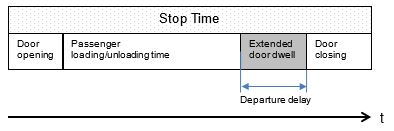

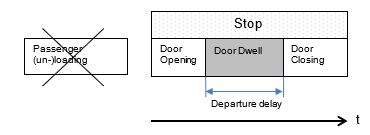

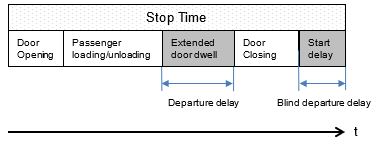

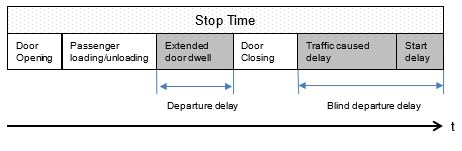

The passenger departure delay with open doors (PDD or PDDOD) is the period of time after passenger transfer is complete until the doors begin to close where there is one measurement for each stop experienced by the passenger. PDD is illustrated in Figure 5.

During passenger loading and unloading times, passengers crossing the cabin door threshold interrupt the passenger detection beams.

Figure 5 General passenger departure delay (normal stop)

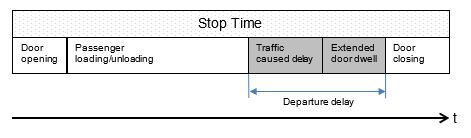

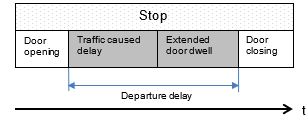

In Figure 6 the PDD is extended because of traffic delays. For example, the dwell time may have been lengthened because another cabin blocks the way of the cabin in a MCLS. Doors are held open for better passenger comfort compared to blind delays with closed doors.

Figure 6 General passenger departure delay (normal stop + traffic caused delay)

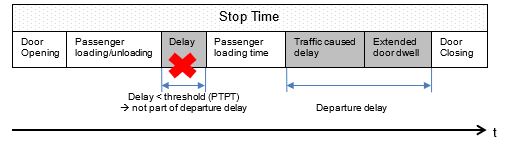

Note 1: If there is a pause in passenger transfer, but the transfer re-starts before the doors start to close because it is less than the door dwell time and it is shorter than a “passenger transfer pause threshold” (PTPT), the departure delay does not start until the end of the final passenger transfer. This is illustrated in Figure 7. A reasonable value of PTPT is 1 sec.

Figure 7 Short pause in passenger transfer

A short pause in passenger transfer can happen between normal unloading and loading of passengers especially where there are thick walls and deep door frames. When passengers are unloading and the walls are thick, door detection beams will be re-established for a short period of time until the loading passengers interrupt the detection beams. These short pauses are not seen as negative system delays.

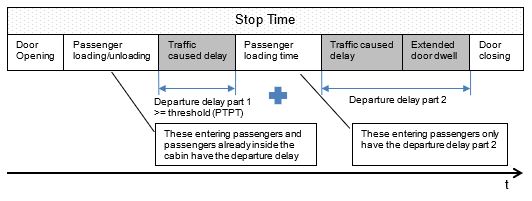

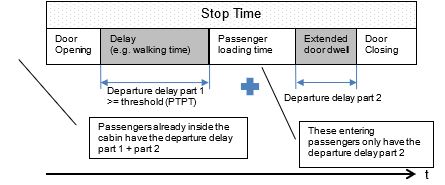

Note 2: If there is a pause in passenger transfer without doors starting to close because of a traffic caused delay that is longer than or equal to a “passenger transfer pause threshold” (PTPT), for passengers already inside the cabin the departure delay includes the time during which there is no passenger transfer (passenger detection beams cleared). This is illustrated in Figure 8.

Figure 8 Pause in passenger transfer

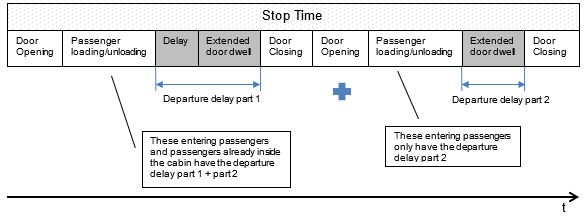

Note 3: If the doors start to close, but are re-opened due to a new call being placed on the system, the departure delay re-starts when the next period of passenger transfer is complete. If the doors repeatedly re-open, there may be multiple periods of departure delay for a single stop, all of which are included in the departure delay for passengers already inside the cabin. This is illustrated in Figure 9.

Figure 9 Door re-opening and departure delays

Note 4: If there is a false stop or passenger transfer finishes before the door is fully open, the time between when the doors are fully open and the time when the doors start closing is considered as departure delays for passengers inside the cabin. This may include door dwell time and traffic caused delays as shown in Figure 10 and Figure 11.

Figure 10 False stop

Figure 11 False stop + traffic caused delay

Note 5: If the passenger transfer is delayed e.g. because of walking times from the call input station to the already waiting cabin, the delay is included in the departure delay for passengers already in the cabin if it is longer than a “passenger transfer pause threshold” (PTPT). This is illustrated in Figure 12.

Figure 12 Delayed passenger transfer

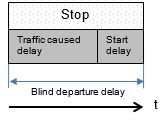

4 Blind Passenger Departure Delays (Closed Doors)

A blind passenger departure delay (BPDD) or passenger departure delay with closed doors (PDDCD) is the time between the instant the doors are fully closed and time the cabin starts moving. In single cabin shafts with no traffic caused departure delay this equates to the motor start delay [13]. This is shown in Figure 13. These start delays are caused by the locking shaft doors, the time required for relays to actuate, and the time required opening the machine brakes before the car starts moving.

Figure 13 Blind departure delay

In a multi cabin lift system blind passenger departure delay can be extended because of traffic, see Figure 14.

Figure 14 Blind departure delay + additional traffic caused delay

Note 6: In systems with multiple cars in the same shaft, where one car is delayed by another and the doors do not cycle during that delay, the departure delay begins as soon as the cabin stops, and ends when the cabin starts to move again. This is illustrated in Figure 15.

Figure 15 Blind stop

5 Cabin Departure Delay

Passenger departure delay (PDD) is a passenger-centric measure, useful in assessing the quality of service from the prospective of the passenger. It is also helpful to have related system based measures for delay [14], cf. passenger waiting time and system response times where the system response time is equal to the waiting time of the first registered landing call of an arriving passenger at a floor [8].

The cabin departure delay (CDD) is the longest passenger departure delay at each stop. It is only measured if there are passengers inside the cabin.

The blind passenger departure delay (BPDD) is the same for all passengers in the cabin. This value is also the blind cabin departure delay (BCDD). It is only measured if there are passengers inside the cabin.

6 Conclusion

This paper describes the causes for departure delays, and defines them such that they can be measured in simulated and real systems. The measures can be used as quality criteria for all known lift systems: conventional one cabin per shaft, two independent cars in one shaft, double deck lift, and circulating multi car lift systems. Because the measure is system independent, the quality of service provided by different lift systems for the same traffic requirements can be compared.

In dispatching, intelligent systems may consider the “cost” of departure delay. Departure delay is part of transit time, but this part of transit time is more “painful” than when the cabin is moving.

Acceptable levels of departure delay have not been assessed and will be a matter of judgement until further studies on the psychology of waiting can provide an objective view.

Glossary

- WT Waiting time (s)

- TT Transit time (s)

- TTD Time to destination (s)

- MCLS Multi car lift system

- PDD Passenger departure delay (s)

- CDD Cabin departure delay (s)

- PTPT Passenger transfer pause threshold (s)

- BPDD Blind passenger departure delay (s)

- BCDD Blind cabin departure delay (s)

REFERENCES

- CIBSE (2015) CIBSE Guide D: 2015 Transportation systems in buildings. London: The Chartered Institution of Building Services Engineers.

- Thumm, G. (2004) A breakthrough in lift handling capacity. In: Elevator Technology 14, Proceedings of Elevcon 2004. The International Association of Elevator Engineers.

- ThyssenKrupp Elevator AG (2014) New era of elevators to revolutionize high-rise and mid-rise construction [online]. Available from: http://www.urban-hub.com/ideas/new-era-of-elevators-to-revolutionize-high-rise-and-mid-rise-construction/ [Accessed 04/20, 2015].

- Smith, R. and Gerstenmeyer, S. (2013) A review of Waiting Time, Journey Time and Quality of Service. In: Symposium on Lift and Escalator Technologies. Northampton:

- Smith, R. and Peters, R. (2004) Enhancements to the ETD Dispatcher Algorithm. In: Elevator Technology 14, Proceedings of Elevcon 2004. The International Association of Elevator Engineers.

- Tanaka, S. and Watanabe, M. (2009) Optimization-based collision avoidance in multi-car elevator systems. In: ICCAS-SICE, 2009.

- Gerstenmeyer, S. and Peters, R. (2016) Multicar dispatching. In: Symposium on Lift and Escalator Technologies. Northampton:

- Barney, G. (2003) Elevator Traffic Handbook. London: Spoon Press.

- Strakosch, G. and Caporale, R. (2010) The Vertical Transportation Handbook, Fourth Edition. Hoboken; New Jersey: John Wiley & Sons, Inc.

- Maister, D. (1985) The Psychology of Waiting Lines [online]. Available from: http://davidmaister.com/articles/the-psychology-of-waiting-lines/ [Accessed 02/12, 2014].

- Fortune, J. (1995) Modern double deck elevator applications and theory. In: Elevator Technology 6, Proceedings of Elevcon 1995. The International Association of Elevator Engineers.

- Norman, D. (2008) The Psychology of Waiting Lines [online]. Available from: http://www.jnd.org/dn.mss/the_psychology_of_waiting_lines.html [Accessed 05/07, 2014].

- Peters, R. (2012) Lift Performance Time. In: Symposium on Lift and Escalator Technologies. Northampton:

- Powell, Bruce. 2015. TWIN simulation.

BIOGRAPHICAL DETAILS

Stefan Gerstenmeyer is working as Senior Engineer and Head of Traffic and Group Control at thyssenkrupp Elevator Innovation GmbH. He has been involved in R&D projects elating to group and dispatcher functions for lift controls including multi car lift systems. He is a post graduated research student at the University of Northampton.

Richard Peters has a degree in Electrical Engineering and a Doctorate for research in Vertical Transportation. He is a director of Peters Research Ltd and a Visiting Professor at the University of Northampton. He has been awarded Fellowship of the Institution of Engineering and Technology, and of the Chartered Institution of Building Services Engineers. Dr Peters is the author of Elevate, elevator traffic analysis and simulation software

Rory Smith is Visiting Professor in Lift Technology at the University of Northampton. He has over 47 years of lift industry experience and has been awarded numerous patents.