Understanding EN 81-77: 2013 & prEN 81-77: 2017. Lifts Subject to Seismic Conditions

Rory S. Smith

University of Northampton

Northampton UK

This paper was presented at The 7th Symposium on Lift & Escalator Technology (CIBSE Lifts Group, The University of Northampton and LEIA) (2017). This web version © Peters Research Ltd 2018

Keywords: Lifts, Standards, Earthquakes

Abstract. Around the Pacific Rim, the potential for earthquakes to severely damage lifts has been recognized for decades. EN 81-77: 2013, enacted in November 2013 now brings seismic standards to the rest of the world. This standard addresses the seismic risks to lifts and establishes standards for mitigation. European Standard prEN 81-77: 2017 makes changes to the existing standard [10].

These standards are explained in practical terms, examples of seismic damage, particularly in California, are explored, and the reduction in damage that has occurred in subsequent earthquakes as a result of new codes enacted after each major earthquake are examined.

1 Introduction

EN 81-77: 2013 states the aims of the standard, describes the hazards to lifts caused by seismic accelerations, defines protective measures that can be taken to deal with the hazards, and quantify anticipated accelerations at a specific site [1].

Before reviewing EN 81-77: 2013, it is important to have an overview of how earthquakes are caused and where they can be expected to occur.

2 Earthquakes

The outermost shell of the earth is made up of Tectonic plates [2]. These individual plates are in contact with each other and in constant motion relative to each other. There are two types of plates; continental and oceanic. The major landmasses are part of the continental plates while most of the ocean’s floor is made up of oceanic plates. Oceanic plates are thinner and denser than continental plates.

The motion between plates is not smooth. The plates are often bound together at a location known as an asperity and remain bound until there is sufficient stress to cause a sudden movement of the plates [3]. These sudden movements are known as earthquakes.

When an oceanic plate and a continental plate converge, the dense oceanic plate is driven under the less dense continental plate. This action is known as subduction [3]. Friction between the plates causes intense heating which melts the rock and the molten rock being less dense that the continental rock rises through the rock and causes volcanos to appear on land. Subduction is not smooth and so the movement causes earthquakes. The Pacific Northwest of the USA, home of the Mt. St. Helens volcano, is an example of this type of convergence.

When two oceanic plates converge, the underwater convergence also involves subduction of the denser of the two plates. Earthquakes are always a part of the subduction process. The friction between the two oceanic plates also melts the rock and creates volcanos that rise above the surface of the sea in the form of island arcs. The Japanese Islands are one such island arc [2].

When two continental plates converge, mountain ranges are formed. The convergence of the Asiatic plate and the India plate has formed the Himalayan Mountains and resulted earthquakes.

When two plates slide past each other they form a transform boundary. The two plates grind against each other creating earthquakes. The San Andreas Fault in California is an example of a transform boundary.

3 The Aim of EN 81-77: 2013

The Introduction of EN 81-77: 2013 states the following [1]:

Avoid loss of life and reduce the extent of injuries

Avoid people trapped in the lift

Avoid damage

Avoid environmental problems related to oil leakage

Reduce the number of lifts out of service

4 Hazards Identified in EN 81-77: 2013

The hazards to lifts identified in EN 81-77: 2013 that can be caused by seismic activity includes the following [1]

- Ropes, belts, chains, and traveling cables can get snagged by components in the hoistway.

- Car frames can become separated from the rails. This can result in collisions with building elements and other lift components.

- Counterweight frames leaving the rails. This has resulted in counterweights colliding with cabs, potentially at rated speed.

- Counterweight filler weights leaving the frame. Falling filler weights can cause damage. A reduction in counterweight mass can result in a loss of traction.

- Hydraulic pipe rupture. Unchecked, pipe rupture can cause a car to fall. Hydraulic fluids, depending on their type, can pollute.

- Hydraulic tank rupture. Hydraulic fluids, in addition to having a potential to pollute can constitute a fire hazard.

- Guide rail deflections that let the car or counterweight leave their guides. This creates a collision hazard.

- Machinery anchorage. Poorly anchored machinery has been known to “dance” across the machine room floor during earthquakes. Such machinery will not be able to function after an earthquake.

- Landing switches and final limit switches that need to be able to withstand the accelerations associated with an earthquake and be guarded against impact by ropes.

- Loss of electrical power. An automatic rescue device can avoid entrapments.

- Car doors can come open and that can permit passengers to become injured. Car door locks can prevent this condition.

5 Design Acceleration

The accelerations that act on the lift as a result of an earthquake are directly related to the damage that the earthquake can produce. The greater the acceleration, the greater the effort required to mitigate the risk. For this reason, the standard requires that a calculation of the potential accelerations at the installation site to be calculated.

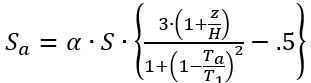

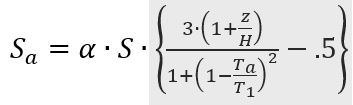

The EN 81-77: 2013 provides the following two formulas are used to calculate design acceleration [1]:

(1)

Where:

αd represents the design acceleration in meters per second squared.

g represents the gravitational acceleration 9.81m/s².

Sα represents a non-dimensional seismic coefficient.

γα represents an importance factor for a building. Minimum value is 1 but could be higher for buildings such as hospitals.

qα represents the behavior factor of an element and has a value of 2.

Where ag represents the ground acceleration expected for a particular location with Type A soil.

Tα represents the fundamental vibration period, expressed in seconds, of the non-structural element. T_a = 0 if the lift does not affect the fundamental vibration period of the building.

T1 represents the fundamental vibration period, expressed in seconds of the building.

z represents the height, in meters, of the non-structural element above the application level of the seismic action.

H represents the building height in meters above the application level of the seismic action.

The values for local accelerations are in documents published by the individual countries. The values of S for the various ground types is shown in Table 1 below taken from EN 1998-1: 2004 [4]:

Table 1 Ground Types and S values

| Ground Type | Description | S |

| A | Rock | 1.0 |

| B | Very dense sand, gravel, or clay | 1.2 |

| C | Dense sand, gravel, or clay | 1.25 |

| D | Loose to medium cohesionless soil or soft to firm cohesive soil | 1.35 |

| E | Surface alluvial layer of C or D, 5 to 20 meters thick over a much stiffer material | 1.4 |

The values of γα are shown in Table 2 taken from EN 1998-1: 2004 below [4]:

Table 2 Building types and importance values

| Importance Class | Building Type | γα |

| I | Buildings of minor importance for public safety, (agricultural buildings, etc.) | 0.8 |

| II | Ordinary buildings, not belonging in other categories | 1.0 |

| III | Buildings whose seismic resistance is of importance in view of the consequences associated with a collapse, (schools, assembly halls, cultural institutions, etc.) | 1.2 |

| IV | Buildings whose integrity during earthquakes is of vital importance for civil protection, (hospitals, fire stations, power plants, etc.) | 1.4 |

The design acceleration formulae can be simplified. In the formula below, q_α is a constant with a value of 2. Therefore the formula can be restated as follows:

(3)

The shaded area, in many cases, has a value of 2.5, because z/H and Tα often have values of zero. Therefore, Sα is as follows:

(5)

Combining the simplified formulae into one formula yields the following:

(6)

It is now possible to understand how the various parameters affect the design acceleration as follows:

The value of α increases in proportion to the magnitude of accelerations at a particular site.

The value of S increases as the soil becomes less solid.

The value of γα increases with the importance of the building.

6 Seismic lift Categories

EN 81-77: 2013 (Table A.1) establishes Seismic Lift Categories based design acceleration. Table 3 defines those categories.

Table 3 Design accelerations and Seismic Lift Categories

| Design acceleration (m/s²) | Seismic lift category | Comment |

| 0 | The requirements of EN 81-20 are adequate. No further actions required | |

| 1 | Minor corrective actions required | |

| 2 | Medium corrective actions required | |

| 3 | Substantial corrective actions required |

7 Corrective measures for Categories 0, 1, 2, and 3

The corrective measures for each category include the corrective measures for categories of a lower number. For example, Category 3 must address the corrective measures for Categories 0, 1, 2, and 3 while Category 2 must only comply with the requirements for 0, 1, and 2. Likewise Category 1 must only comply with Category 0 and 1 requirements.

The corrective measures must be based on the design accelerations for the particular Category. In most cases, design documents must be prepared.

7.1 Category 0

The lift must only comply with EN 81-20.

7.2 Category 1

The following preventive measures are required:

- Prevention of snag points

- Machinery spaces and hoistway located on the same side of expansion joint

- Counterweight retaining devices

- Protection of traction sheaves

- Compensating chain guides

- Precautions against environmental damage

- Guide rail system

- Machinery

- Electrical installations in the hoistway

- Information for use

7.3 Category 2

The following additional preventive measures are required for Category 2:

- Car retaining devices

- Car door locking devices

- Special car behavior in case of power failure

7.4 Category 3

Category 3 requires the following measures in addition to those required for Category 1 and 2:

- Seismic detection system

- Seismic operation mode

- Primary wave detection system (Optional)

8 The California experience

Three major earthquakes in California caused serious lift damage. The earthquakes are known as the 1971 San Fernando Earthquake, the 1989 Loma Prieta Earthquake, and the 1994 Northridge Earthquake. Each earthquake revealed areas that needed protection and caused caused California code changes to be adopted.

8.1 1971 San Fernando Earthquake

At the time this magnitude 6.6 earthquake struck on February 9, 1971, the lift code in place did not address seismic events. 674 counterweights came out of their rails [5].

As a result of the lift damages, the lift code was modified in 1975 and required modifications to virtually all existing lifts.

8.2 1989 Loma Prieta Earthquake

This magnitude 6.9 earthquake struck 70 km south of the San Francisco Bay area on October 17, 1989 [6]. The electrical grid serving the San Francisco Bay area failed near the earthquake’s epicenter. As a result, most elevators were stopped due to lack of power before the seismic waves reached the lifts.

Only 98 counterweights came out of their guides. However, there were 6 car and counterweight collisions that occurred when power was restored. Although, these lifts had seismic switches installed, they were not battery backed up. When the power was returned, the cars were free to run with counterweights out of their guides.

Codes were changed requiring battery back-up or latching contacts on seismic switches.

8.3 1994 Northridge Earthquake

Although this earthquake that struck on January 17, 1994 only was a magnitude 6.7 quake, sensors recorded the highest ground accelerations ever observed in North America. 688 counterweights left their guides [7, 8].

As a result of the experience gained by analyzing the damage caused by this earthquake, seismic codes were established not just in California, but in all of the USA.

9 The updated Standard

European Standard prEN 81-77: 2017 makes changes to the existing standard. The changes are summarized as follows:

- EN 81-20: 2014 and EN 81-50: 2014 are referenced in lieu of EN 81-1 and its revisions.

- Additional references to EN 81-72, Safety rules for the construction and installation of lifts – Particular application for passenger and goods passenger lifts – Part 72: Firefighter lifts.[10]

- Reference is made to EN 81-73, Safety rules for the construction and installation of lifts – Particular application for passenger and goods passenger lifts – Part 73: Behavior of lifts in the event of fire [11].

- Section 5, Protective Measures has some modifications.

- Section 6, Verification of safety requirements and or protective measures has changes in Subsections 6.1 and 6.2.

- Annex C, Primary Wave detection has changes in trigger level and frequency response

- Annex D, Proof of guide rails uses additional parameters in the calculations.

10 Conclusions

Earthquakes are a serious problem in seismically active areas. There are serious costs associated with addressing this problem. However, there are serious consequences if these issues are not addressed. EN 81-77: 2013 addresses this problem.

This standard at first seems complex, however, in its simplified form one can assess its impact on most projects.

REFERENCES

- European Standard EN 81-77: 2013 Safety rules for construction and installation of lifts – Particular Applications for passenger and goods passenger lifts Part 77: Lifts subject to seismic condition.

- Spooner, A. Geology for Dummies. Wiley, Hoboken, (2011).

- Earthquake Glossary Available from: https://earthquake.usgs.gov/learn/glossary/?alpha=ALL Last accessed: 20 June, 2017

- European Standard EN 1998-1: 2004 Eurocode 8. Design of structures for earthquake resistance. General rules, seismic actions and rules for buildings.

- 1971 San Fernando Earthquake Available from: https://en.wikipedia.org/wiki/1971_San_Fernando_earthquake Last accessed: 22 June, 2017

- 1989 Loma Prieta Earthquake Available from: https://en.wikipedia.org/wiki/1989_Loma_Prieta_earthquake Last Accessed: 22 June, 2017

- 1994 Northridge Earthquake Available from: https://en.wikipedia.org/wiki/1994_Northridge_earthquake Last accessed: 22 June, 2017

- FEMA (Federal Emergency Management Agency Reducing the Risks of Non-structural Earthquake Damage Washington, DC, (1994)

- European Standard EN 81-77: 2017 Safety rules for construction and installation of lifts – Particular Applications for passenger and goods passenger lifts Part 77: Lifts subject to seismic condition.

- European Standard EN 81-72, Safety rules for the construction and installation of lifts – Particular application for passenger and goods passenger lifts – Part 72: Firefighter lifts.

- European Standard EN 81-73, Safety rules for the construction and installation of lifts – Particular application for passenger and goods passenger lifts – Part 73: Behavior of lifts in the event of fire.

BIOGRAPHICAL DETAILS

Rory Smith is Visiting Professor in Lift Technology at the University of Northampton. He has over 48 years of lift industry experience during which he held positions in sales, research and development, manufacturing, installation, service, and modernization. His areas of special interest are Machine Learning, Traffic Analysis, dispatching algorithms, and ride quality. Numerous patents have been awarded for his work.